100% Original Filter System - UF Membrane Module 6 inch PVDF Ultrafiltration Membrane Module UFf160 Grinding Waste Water Treatment – Bangmo

100% Original Filter System - UF Membrane Module 6 inch PVDF Ultrafiltration Membrane Module UFf160 Grinding Waste Water Treatment – Bangmo Detail:

Product Overview

UFf160 capillary hollow fiber membrane is high polymer material, which will not have any phase change. Modified PVDF material, which is adopted on this product, has good permeable rate, good mechanical properties, good chemical resistance and pollution resistance. MWCO is 200K Dalton, membrane ID/OD is 0.8mm/1.3mm, filtering type is outside-in.

Applications

- Drinking water treatment of tap water, surface water, well water and river water.

- Pretreatment of RO.

- Treatment, recycle and reuse of industrial waste water.

Filtration Performance

This product is proven to have below filtering effects according to the service?conditions of different water sources:

| Ingredient | Effect |

| SS, Particles?> 1μm | Removal Rate?≥ 99% |

| SDI | ≤ 3 |

| Bacteria, Viruses | >?4 log |

| Turbidity | < 1NTU |

| TOC | Removal Rate: 0-25% |

*Above data is obtained under the condition that feeding water turbidity is < 25NTU.

Product Parameters

Technical Parameters:

| Filtering?Type | Outside-in |

| Membrane?Material | Modified?PVDF |

| MWCO | 200K Dalton |

| Membrane?Area | 40m2 |

| Membrane?ID/OD | 0.8mm/1.3mm |

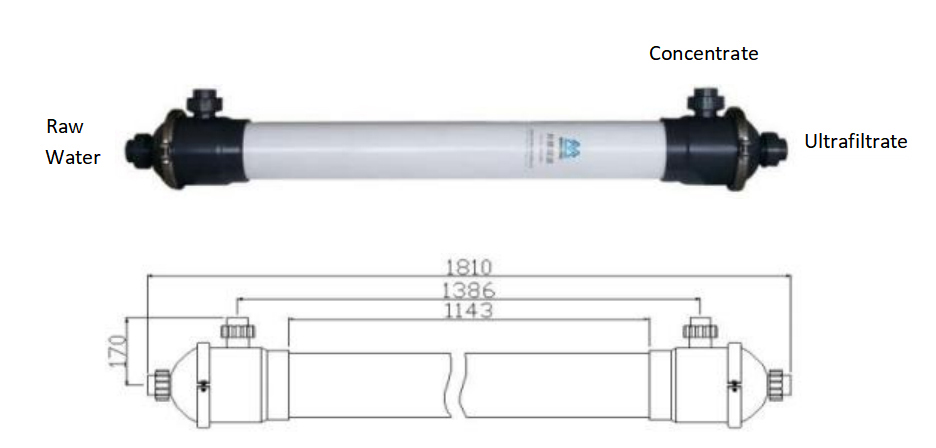

| Dimensions | Φ160mm*1810mm |

| Connector?Size | DN40 Union Joint |

Application Data:

| Pure?Water?Flux | 8,000L/H?(0.15MPa, 25C) |

| Designed?Flux | 40-120L/m2.hr?(0.15MPa, 25C) |

| Suggested?Working?Pressure | ≤ 0.2MPa |

| Maximum?Transmembrane?Pressure | 0.15MPa |

| Maximum?Backwashing?Pressure | 0.15MPa |

| Air?Washing?Volume | 0.1-0.15N m3/m2 .hr |

| Air?Washing?Pressure | ≤ 0.1MPa |

| Maximum?Working?Temperature | 45C |

| PH?Range | Working: 4-10; Washing: 2-12 |

| Operating?Mode | Cross Flow |

Feeding Water Requirements:

Before feeding water, a security filter < 50 μm should be set to prevent blockage caused?by large particles in raw water.

| Turbidity | ≤ 25NTU |

| Oil?&?Grease | ≤?2mg/L |

| SS | ≤ 20mg/L |

| Total?Iron | ≤?1mg/L |

| Continuous?Residual?Chlorine | ≤?5ppm |

| COD | Suggested?≤ 500mg/L |

*Material of UF membrane is polymer organic plastic, there must not be any organic solvents in raw water.

Operating Parameters:

| Backwashing?Flow?Rate | 100-150L/m2.hr |

| Backwashing?Frequency | Every?30-60min. |

| Backwashing?Duration | 30-60s |

| CEB?Frequency | 0-4?times per day |

| CEB?Duration | 5-10min. |

| CIP?Frequency | Every 1-3 months |

| Washing?Chemicals: | |

| Sterilization | 15ppm Sodium Hypochlorite |

| Organic?Pollution?Washing | 0.2%?Sodium Hypochlorite + 0.1% Sodium Hydroxide |

| Inorganic?Pollution?Washing | 1-2% Citric?Acid/0.2% Hydrochloric?Acid |

Component Material:

| Component | Material |

| Membrane | Modified?PVDF |

| Sealing | Epoxy?Resins |

| Housing | UPVC |

Product detail pictures:

Related Product Guide:

The corporation keeps to the operation concept scientific management, superior quality and performance primacy, consumer supreme for 100% Original Filter System - UF Membrane Module 6 inch PVDF Ultrafiltration Membrane Module UFf160 Grinding Waste Water Treatment – Bangmo , The product will supply to all over the world, such as: Los Angeles, Johor, Chicago, Based on our automatic production line, steady material purchase channel and quick subcontract systems have been built in mainland China to meet customer's wider and higher requirement in recent years. We have been looking forward to cooperating with more clients worldwide for common development and mutual benefit!Your trust and approval are satisfactory reward for our efforts. Keeping honest, innovative and efficient, we sincerely expect that we can be business partners to create our brilliant future!

By Lauren from Uruguay - 2018.09.23 17:37

By Lauren from Uruguay - 2018.09.23 17:37

A good manufacturers, we have cooperated twice, good quality and good service attitude.

By Antonio from Ireland - 2018.12.11 14:13

By Antonio from Ireland - 2018.12.11 14:13