Original Factory Membrane Process In Water Treatment - MBR Membrane Module Reinforced PVDF BM-SLMBR-25 Waste Water Treatment – Bangmo

Original Factory Membrane Process In Water Treatment - MBR Membrane Module Reinforced PVDF BM-SLMBR-25 Waste Water Treatment – Bangmo Detail:

Product Overview

MBR is a combination of membrane technology and bio-chemical reaction in water treatment. MBR filter the sewage in bio-chemical tank with membrane so that sludge and water are separated. On one hand, membrane rejects microorganisms in the tank, which greatly increase the concentration of activated sludge to a high level, thus the bio-chemical reaction of sewage degradation processes more rapidly and thoroughly. On the other hand, water output is clear and of high quality because of high precision of membrane.

This product adopts reinforced modified PVDF material, which will not peel or break when backwashing, meanwhile has good permeable rate, mechanical performance, chemical resistance and pollution resistance. ID & OD of reinforced hollow fiber membrane are 1.0mm and 2.2mm respectively, filtration precision is 0.1 micron. Filtration mode is outside-in, that is raw water, driven by differential pressure, permeates into the hollow fibers, while bacteria, colloids, suspended solids and microorganisms etc. are rejected in the membrane tank.

Applications

●Treatment, recycle and reuse of industrial waste water.

●Treatment of refuse leachate.

●Upgrade and reuse of municipal sewage.

Filtration Performance

| No. | Item | Water?Output?Index |

| 1 | TSS | ≤1mg/L |

| 2 | Turbidity | ≤?1 |

Specifications

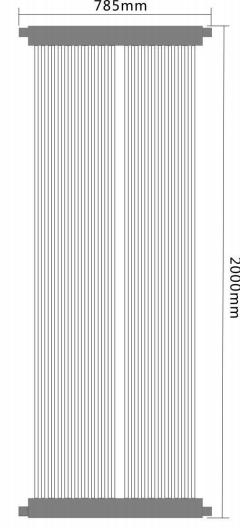

Size

Technical Parameters

| Structure | Outside-in |

| Membrane?Material | Reinforced Modified?PVDF |

| Precision | 0.1 ?micron |

| Membrane?Area | 25m2 |

| Membrane?ID/OD | 1.0mm/ 2.2mm |

| Size | 785mm×2000mm×40mm |

| Joint Size | DN32 |

Component Material

| Component | Material |

| Hollow Fiber Membrane | Reinforced Modified PVDF |

| Sealing Compound | Epoxy Resins + Polyurethane?(PU) |

| Housing | ABS |

Application Parameters

| Designed?Flux | 10~25L/m2.h |

| Backwashing?Flux | 30~60L/m2.h |

| Operating Temperature | 5~45°C |

| Maximum Operating Pressure | -50KPa |

| Suggested?Operating?Pressure | 0~-35KPa |

| Maximum?backwashingPressure | 100KPa |

| Operating Mode | 9min?Operation+1min?Break/8min?Operaetion+2min Break |

| Blowing?Mode | Continuous Aeration |

| Aeration?Rate | 4m3/h.pc |

| Washing Period | Clean?water?backwashing?every?2~4h; CEB?every?2~4 weeks; CIP?every?6~12 months |

Using Conditions

There should be appropriate pretreatments before UF. If defoamer has to be used, please choose alcohol defoamer, silicone defoamer is forbidden.

| Item | Value |

| PH?Range | 5~9 (washing: 2~12) |

| Particle?Size | <2mm, no?sharp?particles |

| Oil & Grease | ≤2mg/L |

| Hardness | ≤150mg/L |

Product detail pictures:

Related Product Guide:

Good quality comes to start with; service is fore; organization is cooperation is our enterprise philosophy which is regularly observed and pursued by our firm for Original Factory Membrane Process In Water Treatment - MBR Membrane Module Reinforced PVDF BM-SLMBR-25 Waste Water Treatment – Bangmo , The product will supply to all over the world, such as: Philadelphia, Greek, Ecuador, Being guided by customer demands, aiming at improving the efficiency and quality of customer service, we constantly improve products and provide more comprehensive services. We sincerely welcome friends to negotiate business and start cooperation with us. We hope to join hands with friends in different industries to create a brilliant future.

By Honorio from Plymouth - 2018.09.08 17:09

By Honorio from Plymouth - 2018.09.08 17:09

High production efficiency and good product quality, fast delivery and completed after-sale protection, a right choice, a nice choice.

By Yannick Vergoz from Lithuania - 2018.11.06 10:04

By Yannick Vergoz from Lithuania - 2018.11.06 10:04